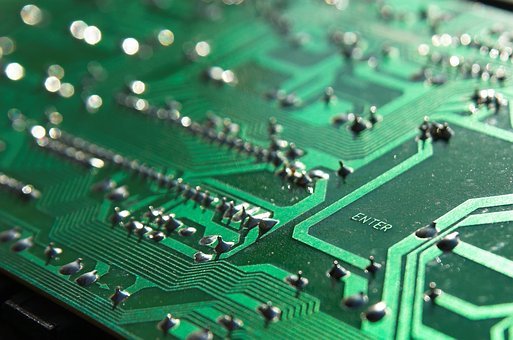

PCB (Printed Circuit Board) na-arụ ọrụ dị mkpa na ndụ taa.Ọ bụ ntọala na okporo ụzọ nke ngwa eletriki.N'akụkụ a, ogo PCB dị oke egwu.

Iji lelee ogo PCB, a ga-emerịrị ọtụtụ ule ntụkwasị obi.Paragraf ndị a bụ mmalite nke ule.

1. Nnwale mmetọ nke ionic

Nzube: Iji lelee ọnụọgụ ion dị n'elu bọọdụ sekit iji chọpụta ma ịdị ọcha nke bọọdụ sekit ò ruru eru.

Usoro: Jiri 75% propanol hichaa ihe nlele.Ions nwere ike igbari n'ime propanol, na-agbanwe conductivity ya.A na-edekọ mgbanwe na conductivity iji chọpụta ntinye ion.

Ọkọlọtọ: ihe na-erughị ma ọ bụ hà nhata 6.45ug.NaCl/sq.in

2. Nyocha nguzogide kemịkalụ nke ihe mkpuchi solder

Nzube: Iji lelee nguzogide kemịkalụ nke nkpuchi solder

Usoro: Tinye qs (kwa afọ juru) dichloromethane dropwise n'elu nlele.

Mgbe obere oge gasịrị, hichaa dichloromethane na owu ọcha.

Lelee ka ị hụ ma owu ahụ agbazere ma ọ bụrụ na agbazere ihe mkpuchi na-ere ahịa.

Ọkọlọtọ: Enweghị esiji ma ọ bụ igbari.

3. Ike ule nke solder nkpuchi

Ebumnuche: Lelee ike nke ihe mkpuchi ihe na-ere ahịa

Usoro: Debe osisi ahụ n'elu ala dị larịị.

Jiri mkpịsị ule ọkọlọtọ kpụrụ ọtụtụ ike n'ime ụgbọ mmiri ahụ ruo mgbe enweghị ncha.

Dekọọ ike nke pensụl kacha ala.

Ọkọlọtọ: Obere ike kwesịrị ịdị elu karịa 6H.

4. Ịkwụsị ike ule

Ebumnuche: Iji lelee ike nwere ike ịdọpụ waya ọla kọpa na bọọdụ sekit

Akụrụngwa: Peel Strength Tester

Usoro: Wepụ waya ọla kọpa ma ọ dịkarịa ala 10mm site n'otu akụkụ nke mkpụrụ.

Debe efere ihe nlele na onye nyocha.

Jiri ike kwụ ọtọ wepụ waya ọla kọpa fọdụrụnụ.

Ike ndekọ.

Ọkọlọtọ: Ike kwesịrị gafere 1.1N/mm.

5. Solderability ule

Nzube: Iji lelee solderability nke pads na site-oghere na osisi.

Akụrụngwa: igwe na-ere ere, oven na ngụ oge.

Usoro: Ime osisi ahụ n'ime oven na 105 Celsius maka awa 1.

Mkpu mmiri.Tinye bọọdụ ahụ nke ọma n'ime igwe na-ere ihe na 235 Celsius C, wee wepụ ya mgbe sekọnd 3 gachara, lelee ebe mpempe akwụkwọ etinyere na tin.Tinye bọọdụ ahụ kwụ ọtọ n'ime igwe a na-ere ere na 235ºC, wepụ ya mgbe sekọnd 3 gachara, wee lelee ma etinyere oghere ahụ na tin.

Ọkọlọtọ: Pasent mpaghara kwesịrị ịdị karịa 95. Ekwesịrị itinye oghere niile na tin.

6. Hipot ule

Ebumnuche: Iji nwalee ikike iguzogide voltaji nke bọọdụ sekit.

Akụrụngwa: Hipot tester

Usoro: Nlereanya dị ọcha ma kpọọ nkụ.

Jikọọ osisi na ihe nleba anya.

Mee ka voltaji gaa na 500V DC (ugbu a na-aga kpọmkwem) na ọnụego adịghị elu karịa 100V/s.

Jide ya na 500V DC maka 30 sekọnd.

Standard: E kwesịghị inwe mmejọ na sekit.

7. Nnwale mgbanwe okpomọkụ iko

Nzube: Iji lelee iko mgbanwe okpomọkụ nke efere.

Akụrụngwa: DSC (iche na-enyocha calorimeter) ihe nleba anya, oven, igwe nkụ, akpịrịkpa eletrọnịkị.

Usoro: Kwadebe ihe atụ, ịdị arọ ya kwesịrị ịbụ 15-25mg.

A na-esi nri ndị ahụ n'ime oven na 105 Celsius maka awa 2, wee mee ka ọ dị jụụ n'ime ụlọ okpomọkụ na ebe a na-ekpo ọkụ.

Tinye ihe nlele ahụ na ọkwa nlele nke DSC tester, ma tọọ ọnụego ọkụ na 20 Celsius C / min.

Nyochaa ugboro abụọ wee dekọọ Tg.

Ọkọlọtọ: Tg kwesịrị ịdị elu karịa 150°C.

8. CTE (ọnụọgụ nke mgbasawanye thermal) ule

Ebumnuche: CTE nke bọọdụ nyocha.

Akụrụngwa: TMA (thermomechanical analysis) tester, oven, dryer.

Usoro: Kwadebe ihe nlele na nha nke 6.35 * 6.35mm.

A na-esi nri ndị ahụ n'ime oven na 105 Celsius maka awa 2, wee mee ka ọ dị jụụ n'ime ụlọ okpomọkụ na ebe a na-ekpo ọkụ.

Tinye ihe nlele ahụ na ọkwa nlele nke TMA tester, dozie ọnụego kpo oku na 10 ° C / min, ma debe okpomọkụ ikpeazụ na 250 ° C.

Dekọọ CTE.

9. Nnwale na-eguzogide okpomọkụ

Ebumnuche: Iji nyochaa nguzogide okpomọkụ nke osisi.

Akụrụngwa: TMA (thermomechanical analysis) tester, oven, dryer.

Usoro: Kwadebe ihe nlele na nha nke 6.35 * 6.35mm.

A na-esi nri ndị ahụ n'ime oven na 105 Celsius maka awa 2, wee mee ka ọ dị jụụ n'ime ụlọ okpomọkụ na ebe a na-ekpo ọkụ.

Tinye ihe nlele ahụ na ọkwa nlele nke TMA tester, ma tọọ ọnụego okpomọkụ na 10 Celsius C / min.

A na-ebuli ihe nlele ahụ ruo 260 Celsius.

Onye nrụpụta igwe mkpuchi mkpuchi ụlọ ọrụ Chengyuan

Oge nzipu: Mar-27-2023